عملية التصميم المخصص

عملية التصميم المخصصة لدينا المكونة من 6 خطوات

الاكتشاف → النموذج الأولي → الامتثال → المشروع التجريبي → الإنتاج الشامل → الدعم

| الخطوة 1: الاكتشاف والتعمق في المتطلبات | |

| أنشطة: • الاستشارات الفنية التفصيلية (الجهد، والمواصفات البيئية، واحتياجات الامتثال) • تحليل جدوى المواد والمكونات • محاذاة الميزانية والجدول الزمني المخرجات: • وثيقة نطاق المشروع الرسمية (معتمدة من قبل كلا الفريقين) لماذا هذا مهم: • يتجنب التحولات المكلفة في منتصف المشروع من خلال تثبيت المواصفات في وقت مبكر. |

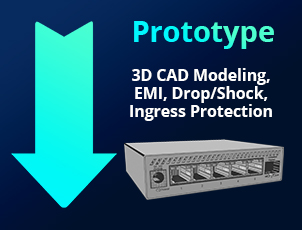

| الخطوة 2: إنشاء النموذج الأولي وإثبات المفهوم | |

| أنشطة: • النمذجة ثلاثية الأبعاد والمحاكاة الحرارية باستخدام برنامج CAD • تجميع النموذج الأولي الوظيفي • اختبارات المعمل (التداخل الكهرومغناطيسي، والسقوط/الصدمة، وحماية الدخول) المخرجات: • نموذج أولي عامل + تقارير الاختبار • ملاحظات حول التصميم للتصنيع (DFM) لماذا هذا مهم: • تحديد العيوب قبل الاستثمار في الأدوات. |

| الخطوة 3: الامتثال والشهادة | |

| أنشطة: • اختبار ما قبل الاعتماد (FCC/CE/UL/إلخ.) • اختبار الإجهاد البيئي (درجة الحرارة والرطوبة والاهتزاز) المخرجات: • خريطة طريق الشهادة (مع الجداول الزمنية التقديرية) لماذا هذا مهم: • يمنع التأخيرات الناتجة عن فشل الامتثال في اللحظة الأخيرة. |

| الخطوة 4: الإنتاج التجريبي والتحقق | |

| أنشطة: • التجميع على دفعات صغيرة (50-100 وحدة) • الاختبار الميداني في العالم الحقيقي (المواقع الشريكة أو البيئات الخاضعة للرقابة) • التحسين بناءً على التعليقات (تبديلات المكونات، وتعديلات البرامج الثابتة) المخرجات: • وحدات تجريبية للتحقق من صحة العميل + تقارير الأداء • قائمة المواد النهائية (BOM) لماذا هذا مهم: • يكتشف مشكلات قابلية التوسع (على سبيل المثال، مشكلات معدل العائد) قبل التشغيل الكامل. • التحقق من صحة سلسلة التوريد - لا يوجد نقص في المكونات في اللحظة الأخيرة. |

| الخطوة 5: الإنتاج الضخم وقابلية التوسع | |

| أنشطة: • الانتهاء من تصنيع الأدوات (القوالب، الأدوات، تجهيزات الاختبار الآلية) • إعداد التصنيع المرن (نقاط تفتيش مراقبة الجودة في كل مرحلة) • تنسيق الخدمات اللوجستية (مراكز المخزون، وخيارات التسليم في الوقت المناسب) المخرجات: • أول تشغيل إنتاجي مع التوثيق الكامل (أدلة التجميع وسجلات مراقبة الجودة) • خريطة طريق التوسع (على سبيل المثال، القدرة على زيادة الإنتاج من 1000 وحدة إلى 50 ألف وحدة شهريًا) لماذا هذا مهم: • يثبت أننا قادرون على التوسع دون انخفاض الجودة - وهو أمر بالغ الأهمية بالنسبة للمشترين من المؤسسات. • يوفر المرونة (على سبيل المثال، دعم الإنتاج الإقليمي). |

| الخطوة 6: الدعم مدى الحياة والتحسين المستمر | |

| أنشطة: • إدارة التقادم (مراقبة دورة حياة المكونات، وتنبيهات إعادة التصميم) • تحليل الأعطال وإصلاح الأسباب الجذرية (تكامل عملية RMA) • تحديثات البرامج الثابتة/البرمجيات (تصحيحات الأمان، ترقيات الميزات) المخرجات: • ضمان دعم المنتج لمدة 5 سنوات أو أكثر (قابل للتمديد) • إشعارات نهاية العمر الافتراضي (EOL) قبل 12 شهرًا أو أكثر لماذا هذا مهم: • يقلل من التكلفة الإجمالية للملكية على المدى الطويل - لا توجد تكاليف استبدال مفاجئة. • تعزيز الشراكات - يعود العملاء لشراء تصميمات الجيل الثاني. |

على عكس الشركات المصنعة للمعدات الأصلية، فإننا نتعامل مع مشروعك باعتباره تعاونًا طويل الأمد - وليس طلبًا لمرة واحدة.

هل أنت مستعد لبدء مشروع OEM المخصص الخاص بك؟

احصل على تدقيق التصميم المجاني الخاص بك: [ sales@benchu-group.com ]

هل تريد تقديرًا سريعًا لمشروع OEM الخاص بك؟

تحدث مع المهندس الآن: [ سكايب: harry1598 ]